Wholesale N2O Cream Charger Cylinders

Looking to enhance your product range with lightweight and durable aluminum cream chargers? Our custom-designed, factory-direct N₂O aluminum cylinders deliver outstanding performance—offering a strong, corrosion-resistant build with a sleek, modern finish. Engineered for optimal efficiency and strong resale value, these chargers are a premium choice for distributors aiming to elevate their brand. With competitive pricing and exceptional reliability, our aluminum cylinders make a smart addition to any business. Get in touch today to discover how our cutting-edge solutions can give you a competitive edge!

Thank you for reading this post, don't forget to subscribe!Your Trusted Source for N2O Aluminum Cream Chargers

At Guizhou Chunsheng Qihan Gas Technology, we craft premium aluminum cream chargers engineered to give your brand a distinct advantage. Lightweight, corrosion-resistant, and more durable than traditional steel options, our aluminum cylinders offer superior performance while cutting down on shipping expenses.

Whether you need standard solutions or fully customized designs, we tailor every product to match your brand’s exact requirements. Each unit is put through stringent quality checks to guarantee exceptional safety and reliability.

As the only manufacturer in China producing both steel and aluminum cylinders, we combine cutting-edge technology with high-capacity production to meet large-scale demands efficiently—keeping your business competitive and future-ready.

Choose aluminum—where performance meets profit.

Select from our best-selling sizes: 0.47L (330g) and 0.95L (640g). Need something more specific? We offer full customization to meet your precise needs.

From tailored dimensions and gas blends to custom labels and packaging, our flexible solutions help your product stand out and make a lasting impact in the market.

Why Choose Aluminum Over Steel?

Best Suited For These Buyer Types

Aluminum N₂O cylinders are the top choice for businesses seeking superior quality, distinctive design, and streamlined operations. Here’s who benefits most:

🧃 Brand Owners & Private Label Developers

Aiming to project a premium brand image? Our seamless, weld-free aluminum cylinders deliver a sleek, modern aesthetic—perfect for upscale packaging. Customize with your unique flavors, colors, and branding to stand out in competitive markets.

📦 Wholesalers & Importers

Want to cut down on shipping costs and simplify logistics? Aluminum cylinders weigh up to 50% less than steel, making transport more efficient while offering excellent durability and corrosion resistance.

🏪 Retail Buyers & Supermarket Chains

Need a polished appearance, extended shelf life, and full certification support? Aluminum options are rust-proof, fully compliant, and ready for display—ideal for both physical retail and online distribution.

Customized Cylinder Flavor: Enhance the user experience with unique flavors.

Enhance your product’s appeal with customized gas flavors. Just let us know your desired flavor, and our seasoned experts will create the perfect match to meet your needs.

WATERMELON FLAVOR

STRAWBERRY FLAVOR

PINEAPPLE FLAVOR

MANGO FLAVOR

Customizing Cylinder Bases, Latex Caps, and Nozzles

Enhance your brand presence by personalizing the colors of your cylinder’s plastic components. Select the ideal hues for the base, latex cap, and nozzles to create a distinctive look. Customize every element and let your product make a lasting impression!

New plastic nozzle customization

Fruit flavor plastic nozzle customization

Plastic base customization

Latex cap customization

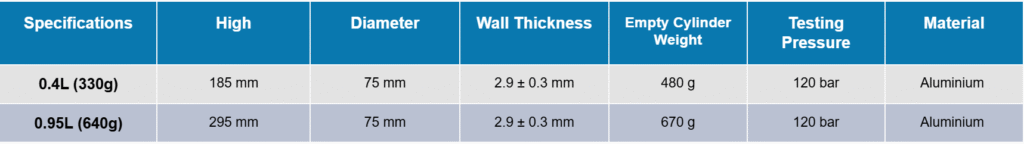

Product Parameters Specifications

Discover the Most Comprehensive and Accurate Specifications for Cream Charger Cylinders Online

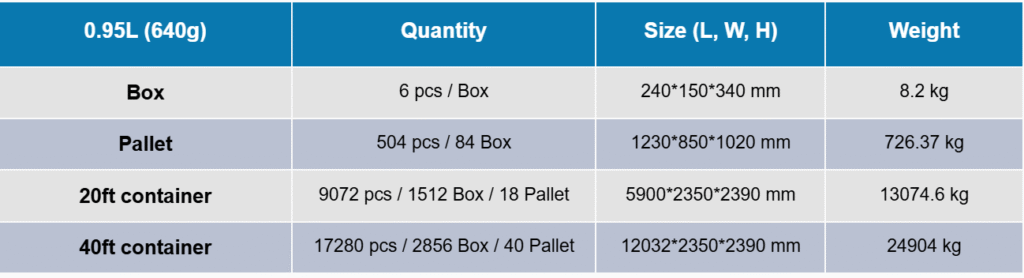

Transport loading parameters

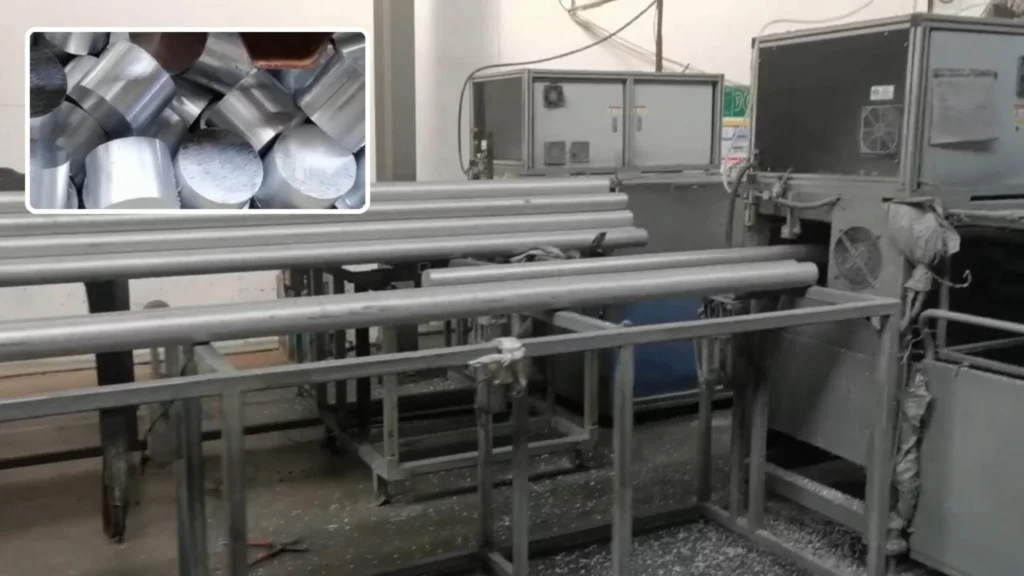

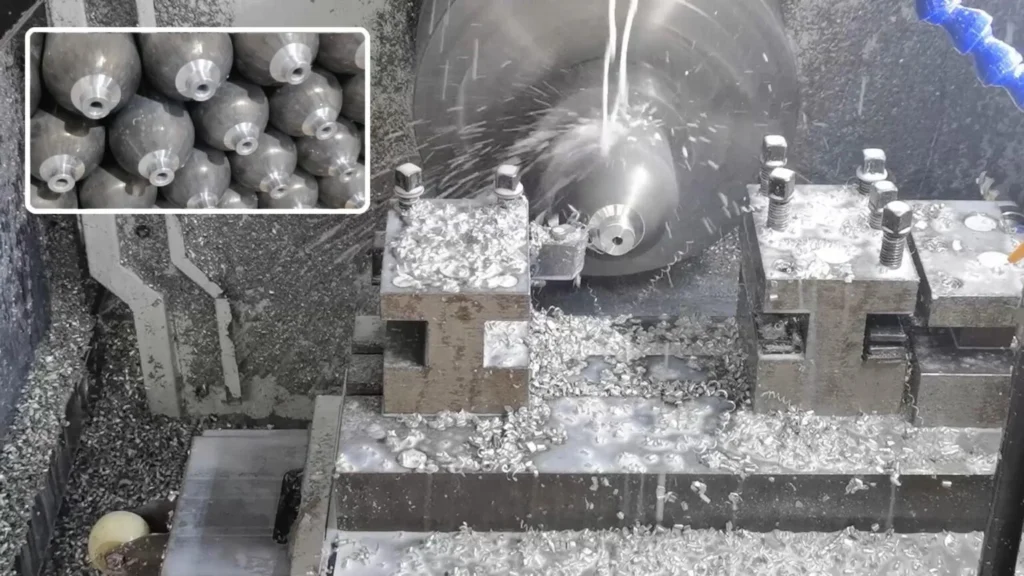

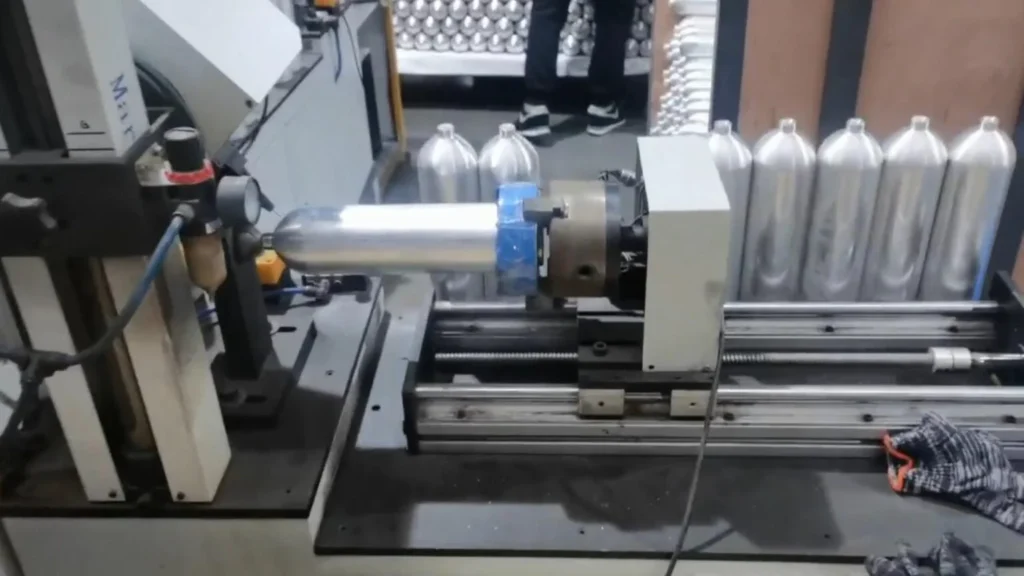

Production process

Explore the Full Production Process Behind Your Cream Chargers—See How Quality is Made

1. Cutting aluminum strips

2. Immersing aluminum blocks in lubrication tanks

3. Lubricated blanks are placed in heating furnaces

4. Hot extrusion and deep drawing of aluminum blocks into cylinders

5. Closing the top of the cylinder

6. Solution hardening - quenching - aging

7. Drilling and threading

8. Hydraulic testing

9. Burst testing

10. Engraving the factory number

11. Cleaning